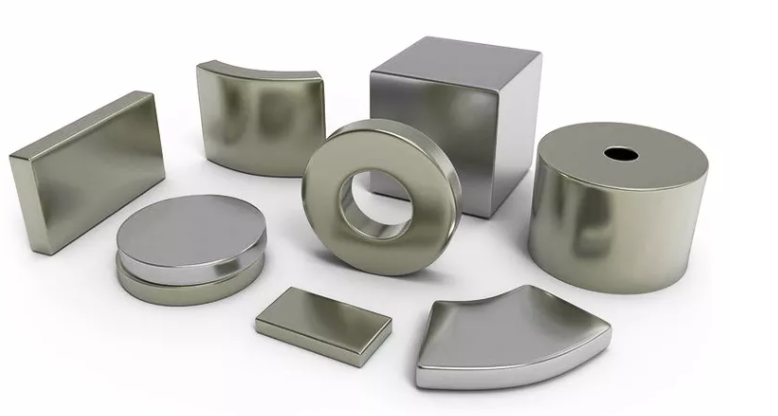

1. Cov hlau nplaum neodymium feem ntau yog ua los ntawm cov hmoov hlau ntawm neodymium, hlau, thiab boron uas yog sintered ua ke nyob rau hauv high kub thiab siab los tsim cov khoom tiav.

2. Cov hmoov sib tov yog muab tso rau hauv pwm los yog thawv thiab rhuab mus rau qhov kub siab kom nws pib yaj thiab fuse.

3. Thaum cov khoom mus txog nws qhov melting point, nws tau tuav ntawm qhov kub no rau ib lub sij hawm kom txog rau thaum nws solidifies rau hauv ib daim uas tsis muaj qhov khoob los yog tawg ntawm cov khoom.

4. Tom qab solidification tau tshwm sim, cov hlau nplaum tuaj yeem raug machined rau hauv nws qhov kev xav tau thiab loj siv ntau yam cuab yeej txiav xws li milling tshuab lossis lathes nyob ntawm daim ntawv thov tshwj xeeb.

5. Cov npoo ntawm cov hlau nplaum tuaj yeem ua polished yog tias xav tau ua ntej coated nrog kev tiv thaiv plating xws li npib tsib xee lossis zinc rau kev tiv thaiv corrosion.

Kev ua kom paub meej ntxiv, thov ua siab zoo saib daim ntawv qhia hauv qab no:

| Tsis muaj. | Txheej Txheem Flow | Kauj ruam ntau lawm | Kev ua haujlwm thev naus laus zis |

| 1 | Kev tshuaj xyuas raw khoom | 1.ICP-2.Chemical Analysis-3.Analyser(C&S) | Rohs Detection Kev Ntsuas Kev Ntsuas Purity Analysis |

| 2 | Raw Khoom Ua Ntej Kev Kho Mob | 4.Sawing- 5. Drying- 6.Impact Cleaning | Sawing Hlau Cua kub kom qhuav Impact ntxuav |

| 3 | Cov khoom xyaw tswj | 7.Cov khoom xyaw tswj | Weigh Batching Mix Raw Khoom |

| 4 | Sawb Casting | 8.Vacuumizing-9.Melting-10.Casting | Nqus tsev Melting Smelting Casting |

| 5 | Hydrogen Decrepitation | 11.Pre-treating-12.Vacuumizing-13.Add Hydrogen | Kev kho mob ua ntej Nqus tsev Demolish los ntawm Hydrogen |

| 6 | Milling | 14.Shattering-15.Grinding-16.Jet Mill-17.Granularity Control | Kev tawg Sib tsoo Dav Hlau Kev ntsuas ntsuas |

| 7 | Nias | 18. hmoov hnyav -19.Pre-pressing - 20.Nias -21. Isostatic nias | Hmoov hnyav Ua ntej nias Nias Isostatic nias |

| 8 | Sintering | 22.Vacuumizing- 23.Sintering -24 Kev kho cua sov | Nqus tsev Sintering Kev kho cua sov |

| 9 | Kev tshuaj xyuas | 25. BH-26. PCT-27. Kev ntsuas qhov ntom ntom -28.Roughcast Inspection | Sib nqus ntsuas Kev ntsuas kub coefficient PCT Kev ntsuas ceev Kev tshuaj xyuas |

| 10 | Tshuab dhos | 29.Grinding -30.Wire txiav-31.Inner hniav txiav | Sib tsoo Hlau txiav Sab hauv hniav txiav |

| 11 | QC qauv kuaj | 32.QC qauv kuaj | QC qauv kuaj |

| 12 | Chamfering | 33. Kev sib tw | Chamfering |

| 13 | Electroplating | 34.Electroplating Zn 35. Electroplating NICUNI 36.Phosphating 37. Tshuaj Ni | Electroplating Zn Electroplating NICUNI Phosphating los yog Chemical Ni |

| 14 | Txheej tshuaj xyuas | 38.Thickness-39.Corrosion Resistance -40. Adhesiveness-41.-Kev soj ntsuam siab | Thickness Corrosion Resistance Adhesiveness Kev soj ntsuam siab ntev |

| 15 | Magnetization | 42.Complete Inspection- 43.Marking- 44.Arraying/Involution- 45.Magnetizing | Kev soj ntsuam kom tiav Kos npe Arraying/Involution Magnetizing Sib Nqus Fiux Test |

| 16 | Ntim | 46. Sib Nqus Flux- 47.Bagging- 48. Ntim | Hnab ntim khoom Ntim |

Post lub sij hawm: Feb-15-2023